Radial Features

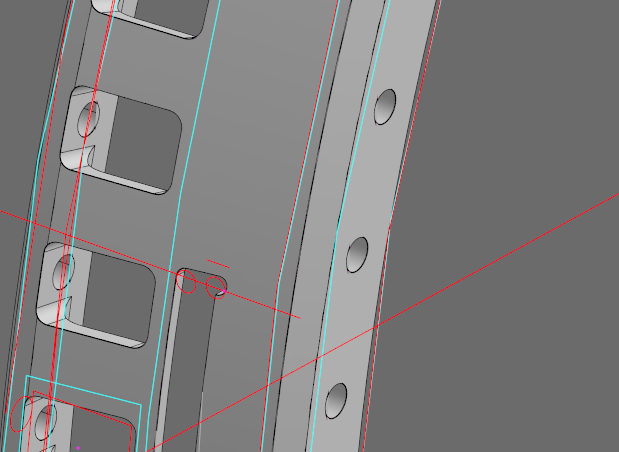

Anyone have any experience with measuring size and location of radial features? We have a part that is essentially a steel hoop with a bunch of rectangular windows cut into the outside surface. In order to reach most of the features, we have it oriented vertically as opposed to horizontally. It looks like this:

The circular holes on either side are no problem because they are lying perfectly within the ZX plane.

The square rectangular holes are giving us a problem. Measuring them as a square slot, we seem to be getting reliable results for the size, but the locations are always off. This doesn't make sense to us because they were machined in the same operation as the round holes, and they check in the ballpark using hard methods.

Should we be using any particular technique for measuring/reporting features that are not parallel to a particular measuring plane?

Topic Participants

Gary King

Michael York

john.peterson